Welcome to Southampton Vapour Blast Services

Please also visit our sister website https://tedsshed.co.uk for other services we provide not related to cleaning/blasting.

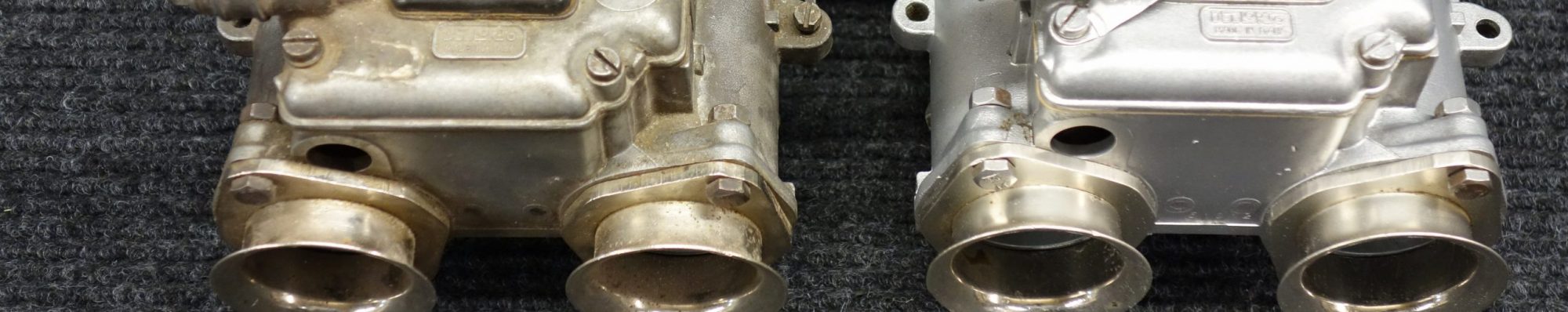

Southampton Vapour Blast Services

Specialists in Vapourblasting & Dryblasting

Welcome to Southampton Vapour Blast Services

Please also visit our sister website https://tedsshed.co.uk for other services we provide not related to cleaning/blasting.